Suitable for all kinds of knitted/woven fabrics

(Cotton,silk,wool,polyester,acetate,nylon,blended fabric,linen,etc)

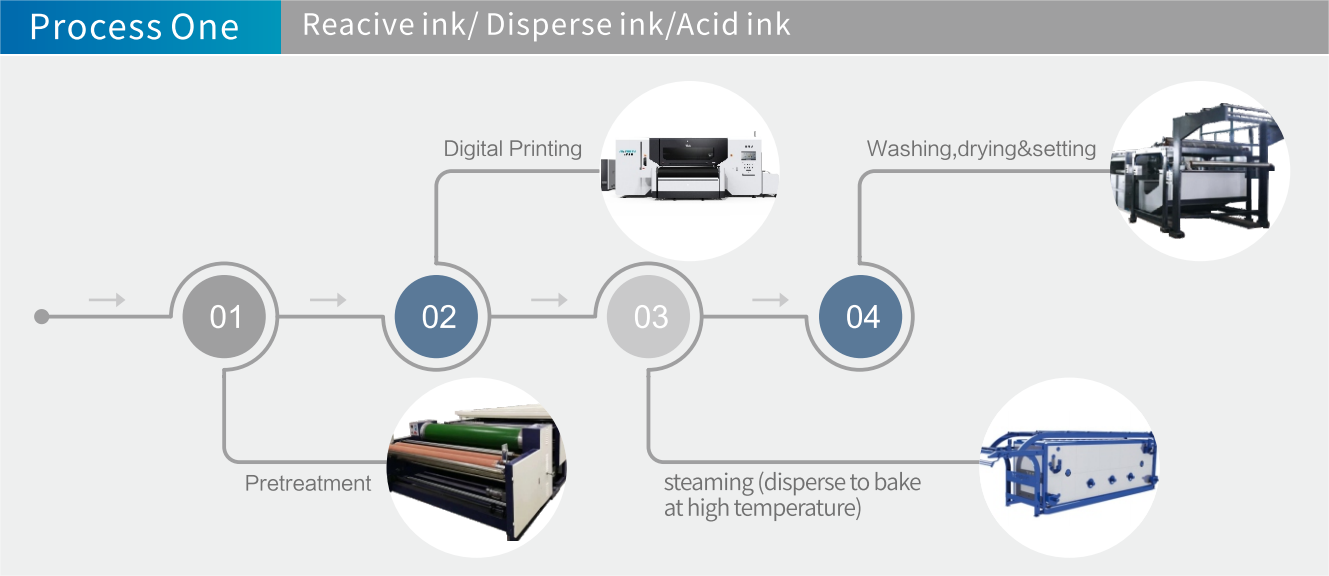

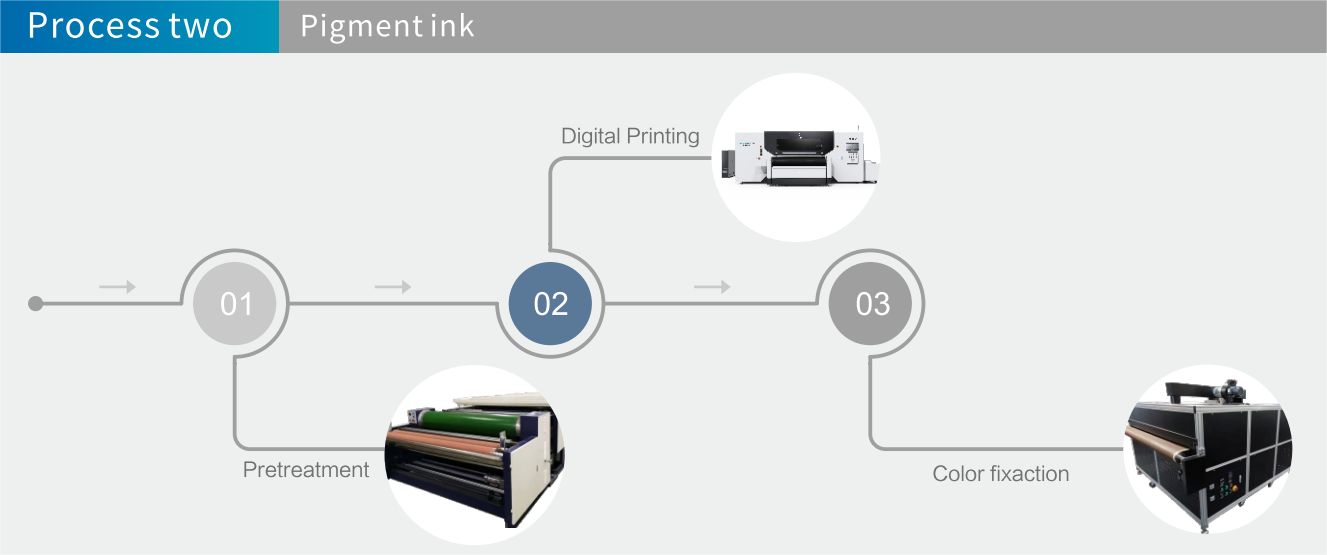

Printing Process

FOUR KINDS OF INK, ACCORDING TO THE DIFFERENT FABRICS TO CHOOSE DIFFERENT INKS.

| Name | Scope ofapplication | Advantage |

| Reactive Ink | Suitable for cotton, rayon, silk and natural fibre fabrics | 1.Process shorten,goodeffect. 2.Personalized customization, no limited by color 3.Low pollution. |

| Disperse Ink | Disperse ink direct printing: Suitable for polyester fabrics. | 1.Good penetration,color, fastness migration. 2.Personalized customization, no imited by color. 3.Low pollution. |

| AcidInk | suitable for silk, wool,nylon etc. | Bright colors |

| Pigment Ink | use for any kinds fabric. | 1.Environmental,no need washing. 2.Printing process is simple. 3.Sample printingin minutes. 4.Can be used for all fabrics. |

DIFEENT INK,THE PROCESSING IS DIFFERENT.THERE ARE TWO PROCESSING AS BLOWS

| Product mode | HOLDWIN-R1832/2232/2632 | |

| Print head | Ricoh GEN5E/GEN6 | |

| Fabric conveyance mode | Adhesive belt with cleaning and heating system | |

| MaximumPrint width | 1900/2200/2600mm | |

| Speed | Gen6 | 1 pass:1300m²/h 2 pass:650m²/h |

| Maximum printing resoution | 2400 DPI | |

| RIP software | Neostampa/Texprint(origin) | |

| Printing partintroduction | Automatic negative pressure inksupply, automatic carlifting, automatic positive pressure cleaning,automatic moisturizing, sprinkler anti-collision system. | |

| Main ink tank | 15L | |

| Belt system introduction | Automatic drying and winding system,automatic cleaningguide belt system,anti-pressure rollerprint,synchronous pressure roller | |

| Dryer unit | 3 tiers industry dryer with off plane | |

| Ink Type | reactive/disperse/acid/pigmentink | |

| InterfacePower voltage | Optical fiber | |

| Print head height | Height adjustable 1.5-30mm,to adapt medium of different thickness | |

| Power voltage | 380V,3L+N+G(with independent reliable effective earth wire) | |

| Power frequency | 50HZ/60HZ±1HZ | |

| Power Consumption | Printer:40kw; oven:6KW | |

| Workshop Condition | Temperature:20-30℃,humidity:50-65% | |

Effective width

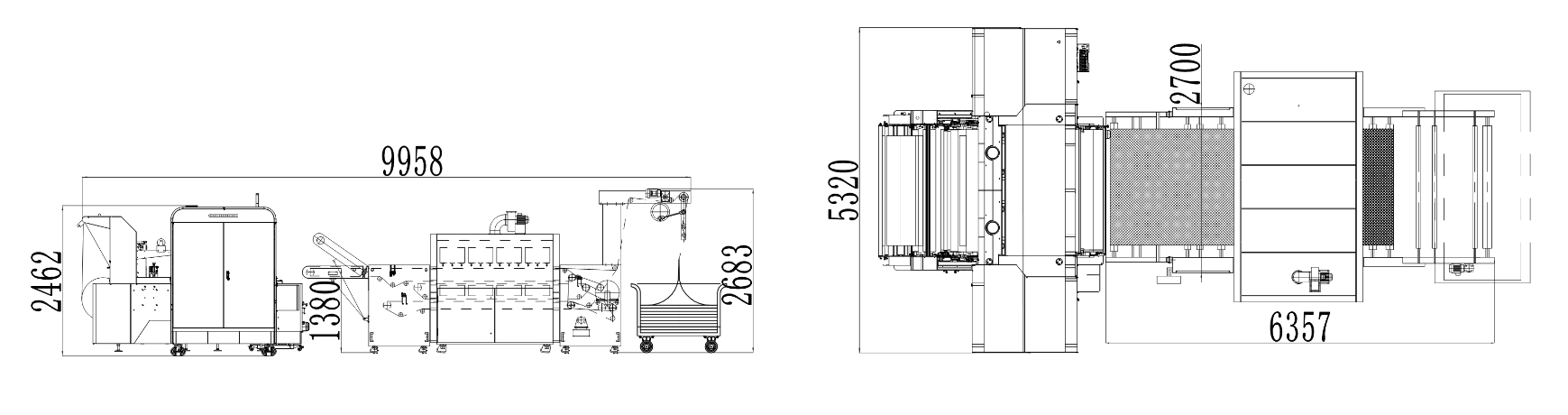

| Size | 1900mm | 2200mm | 2600mm | |

| Printer | 5300mm*3450mm*2220mm(L*W*H) | 5700mm*3450mm*2220mm(L*W*H) | 6100mm*3450mm*2220mm(L*W*H) | |

| Dryer | 6400mm*3800mm*2700mm(L*W*H) | 6800mm*3800mm*2700mm(L*W*H) | 7200mm*3800mm*2700mm(L*W*H) | |

| Ink Cabinet | 1760mm*700mm*995mm(L*W*H) | |||

| Weight | Printer:6200Kg; The bakery:5000kg; |

Printer:8000Kg; | Printer:10000Kg; | |

Q&A

Q: What is the product model of this printer?

A: The product mode is HOLDWIN-R1832/2232/2632.

Q: Which print head does it use?

A: It uses Ricoh GEN5E/GEN6 print heads.

Q: How does the fabric conveyance work in this machine?

A: Fabric conveyance is done through an adhesive belt with cleaning and heating system.

Q: What is the maximum print width for each pass?

A: The maximum print width is 1900/2200/2600mm.

Q: What is the speed of printing on Gen6?

A: On Gen6, the speed is 1300m²/h for one pass and 650m²/h for two passes.

Q: What software is used for RIP?

A: Neostampa/Texprint is used for RIP.

Q: What is the main ink tank capacity?

A: The main ink tank has a capacity of 15L.

Q: Does the machine have an automatic drying and winding system?

A: Yes, the machine has an automatic drying and winding system.

Q: How many tiers does the industry dryer have?

A: The dryer unit has three tiers with off-plane drying.

Q: What types of ink can be used in this printer?

A: Reactive/dispersive acid/pigment ink can be used.

Q: Is there any optical fiber interface available?

A: Yes, there is an optical fiber interface available.

Q: Can the print head height be adjusted?

A: Yes, the print head height is adjustable from 1.5-30mm to adapt to medium thickness fabrics.

Q: What is the power voltage required for this machine?

A: The power voltage required is 380V, 3L+N+G (with independent reliable effective earth wire).

Q: What is the frequency and hertz needed for operation?

A: The frequency and hertz needed are 50HZ/60HZ±1HZ.

Q: What is the power consumption of the printer and oven?

A: The power consumption of the printer is 40kw and the oven is 6KW.

Q: What are the workshop conditions required for operation?

A: The temperature should be between 20-30°C and humidity should be between 50-65%.

Zhiyu is passionate about good products, good services, and good prices to let consumers know that choosing us is the right choice! For partners and end customers, we will provide one-on-one considerate smart services and provide you with more high-quality procurement solutions.