Digital printing technology has revolutionized the textile industry, transforming how designs are transferred onto fabrics and enabling a new era of creativity and efficiency. From its humble beginnings to the sophisticated systems we have today, digital printing has continually evolved, driven by technological advancements and changing market demands. This article explores the journey of digital printing technology, highlighting key milestones, current trends, and future prospects, while emphasizing HOLDWIN’s role in shaping this dynamic industry.

Digital printing began as a niche technology in the late 20th century, primarily used for short-run and specialty applications. Early digital printers were limited by low resolution and slow print speeds, making them unsuitable for large-scale textile production. However, they offered unique advantages over traditional printing methods, such as the ability to produce complex, multi-colored designs without the need for screens or plates.

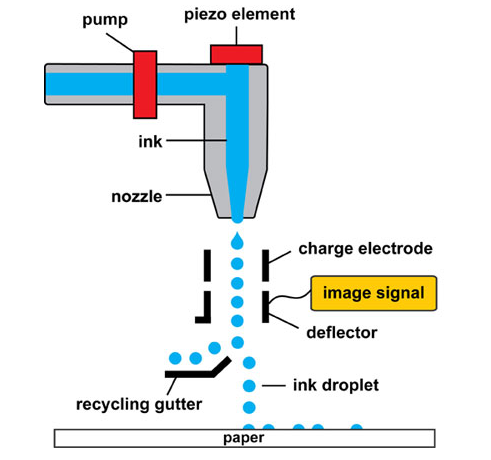

Inkjet printing emerged as a game-changer in the digital printing landscape. This technology uses small nozzles to spray tiny droplets of ink onto the fabric, allowing for high-resolution images and vibrant colors. The development of advanced inks and print heads significantly improved print quality and speed. Sublimation and heat transfer technologies further expanded the capabilities of inkjet printers, enabling the production of durable, high-quality prints on various textile materials.

The introduction of UV (ultraviolet) and solvent printing technologies marked another significant advancement in digital printing. UV printing uses ultraviolet light to cure or dry the ink as it is printed, resulting in fast production speeds and exceptional durability. This technology is particularly suited for printing on non-porous materials, such as synthetic fabrics. Solvent printing, on the other hand, utilizes solvent-based inks that are ideal for outdoor applications due to their resistance to fading and weathering.

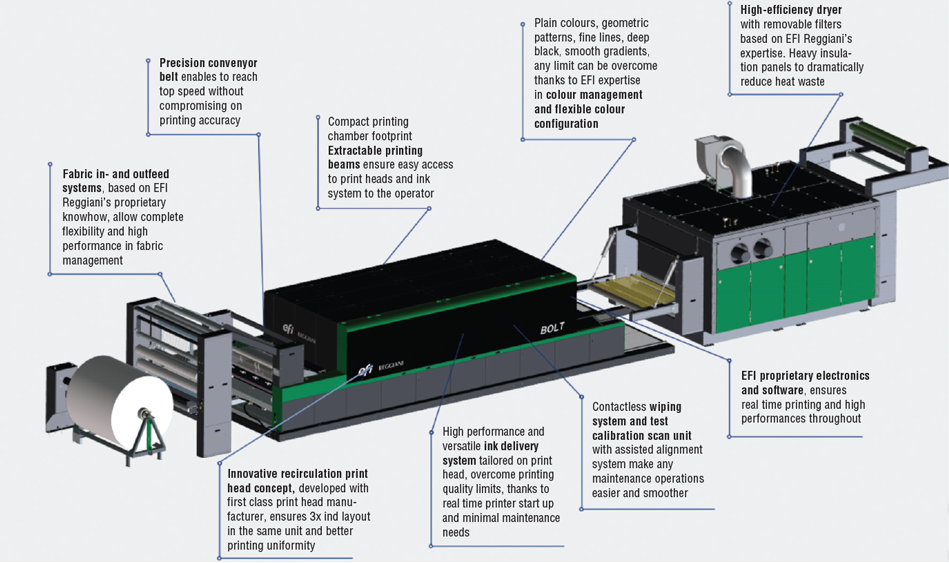

Direct-to-fabric (DTF) printing has emerged as a versatile and efficient technology for the textile industry. Unlike traditional printing methods that require multiple steps, DTF printing transfers ink directly onto the fabric in a single pass. This technology supports a wide range of materials, from natural fibers to synthetic blends, and offers superior color accuracy and fast turnaround times. HOLDWIN has been at the forefront of DTF innovation, developing machines that deliver consistent, high-quality results.

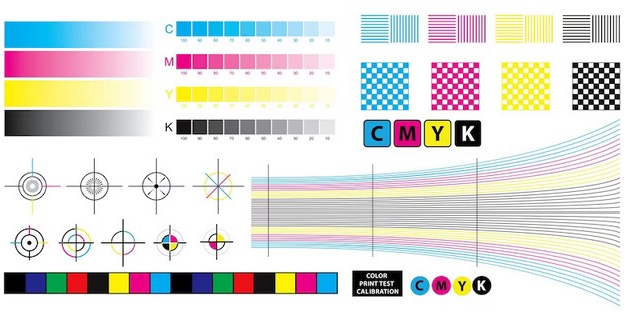

Effective color management is crucial in digital textile printing, ensuring that the colors on the screen match the final printed product. This involves calibrating printers, monitors, and software to maintain color consistency across different devices and materials. Understanding the properties of various textile materials is also essential, as factors such as fabric type, weave, and finish can impact print quality. HOLDWIN’s expertise in color management and material science allows us to provide tailored solutions for diverse customer needs.

The future of digital printing technology looks promising, with ongoing research and development aimed at enhancing print quality, speed, and sustainability. Innovations such as 3D printing on textiles, biodegradable inks, and smart fabrics are poised to redefine the industry. Additionally, the integration of artificial intelligence (AI) and machine learning (ML) into digital printing systems will enable greater automation and precision. HOLDWIN is committed to staying at the cutting edge of these developments, continuously improving our products to meet the evolving demands of the global market.

The evolution of digital printing technology has transformed the textile industry, offering unprecedented opportunities for creativity, efficiency, and customization. From the early days of inkjet printing to the latest advances in DTF and UV technologies, digital printing continues to push the boundaries of what is possible. At HOLDWIN, we are proud to contribute to this exciting journey, providing innovative solutions that meet the diverse needs of our customers worldwide. Our commitment to excellence and continuous improvement ensures that we remain a leader in the digital textile printing industry.

“As a fashion designer, I rely on HOLDWIN’s digital printing machines for their unmatched quality and reliability. Their advanced DTF technology allows me to bring my designs to life with stunning detail and vibrant colors. The team at HOLDWIN is always responsive and supportive, making them a valuable partner in my creative process.” – Sarah Thompson, Fashion Designer

By staying at the forefront of digital printing technology, HOLDWIN continues to set new standards in the industry, providing high-quality, innovative solutions that cater to the evolving needs of our global clientele.

Zhiyu is passionate about good products, good services, and good prices to let consumers know that choosing us is the right choice! For partners and end customers, we will provide one-on-one considerate smart services and provide you with more high-quality procurement solutions.