Digital printing technology has revolutionized the textile industry, offering numerous advantages over traditional printing methods. As a media operations specialist at Shaoxing Zhiyu Digital Technology Co., Ltd., I am excited to share the benefits of digital printing, particularly in our brand HOLDWIN, which is dedicated to professional technical training and personalized custom solutions for various textile products such as clothing, towels, scarves, and carpets. This article explores the key benefits of digital printing over traditional methods, highlighting how this innovative technology is transforming the textile industry.

In the ever-evolving world of textile manufacturing, the transition from traditional printing methods to digital printing has marked a significant technological advancement. Traditional methods like screen printing and rotary printing have been the mainstay for decades, but they come with limitations that digital printing effectively overcomes. Digital printing offers enhanced efficiency, versatility, and sustainability, making it an ideal choice for modern textile manufacturers and designers. This article delves into the myriad benefits of digital printing, showcasing why it is increasingly becoming the preferred method in the textile industry.

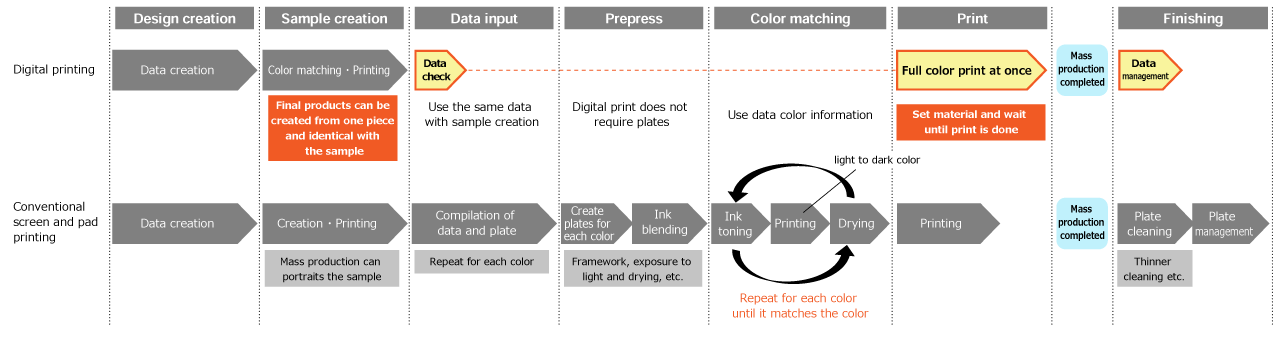

One of the most compelling advantages of digital printing is its efficiency and speed. Unlike traditional methods that require extensive setup times and manual labor, digital printing allows for rapid turnaround. With digital printing, designs can be directly sent from the computer to the printer, eliminating the need for screens and other intermediate steps. This significantly reduces production time, enabling manufacturers to meet tight deadlines and quickly respond to market demands.

Digital printing offers unparalleled versatility and customization options. Traditional methods are limited by the number of colors they can use and the complexity of the designs they can produce. In contrast, digital printing allows for the use of an unlimited color palette and the creation of intricate, high-resolution designs. This makes it possible to produce customized textiles with unique patterns and color schemes, catering to the specific needs and preferences of customers.

Digital printing is more cost-effective than traditional methods, particularly for small and medium-sized production runs. Traditional methods require significant upfront investments in screens, plates, and other equipment. Digital printing, on the other hand, eliminates these costs, making it more accessible and affordable for smaller businesses. Additionally, digital printing minimizes waste, as it only uses the exact amount of ink needed for each print, further reducing costs.

The quality of prints produced by digital printing is superior to traditional methods. Digital printing delivers precise and consistent results, with sharp details and vibrant colors that remain true to the original design. The technology also allows for better color management, ensuring that the final product accurately reflects the intended design. This high level of quality is particularly important for textile manufacturers and fashion designers who require precise color matching and intricate patterns.

In today’s eco-conscious world, the environmental impact of production methods is a critical consideration. Digital printing is more environmentally friendly than traditional methods, as it uses less water and produces less waste. Traditional printing processes require large amounts of water for washing screens and removing excess dyes, leading to significant water pollution. Digital printing, however, is a dry process that reduces water usage and minimizes the release of harmful chemicals into the environment.

Digital printing technology is compatible with a wide range of textile materials, including natural fibers like cotton and silk, as well as synthetic fibers like polyester and nylon. This flexibility allows manufacturers to produce a diverse array of products, from everyday apparel to specialized technical textiles. Additionally, digital printing can be used on both woven and knitted fabrics, further expanding its application range.

Digital printing represents a transformative shift in the textile industry, offering numerous benefits over traditional printing methods. Its enhanced efficiency, unmatched versatility, cost-effectiveness, superior print quality, sustainability, and material flexibility make it an ideal choice for modern textile manufacturers and designers. At HOLDWIN, we are committed to leveraging the advantages of digital printing to deliver high-quality, customized solutions to our customers, ensuring we remain at the forefront of the industry.

“Since switching to HOLDWIN’s digital printing technology, we’ve seen a remarkable improvement in our production efficiency and print quality. The ability to customize designs quickly and affordably has given us a competitive edge in the market. We couldn’t be happier with the results!” – Maria Hernandez, Textile Manufacturer

By embracing digital printing, HOLDWIN is well-positioned to lead the textile industry into a new era of innovation and sustainability. Our commitment to quality, customization, and environmental responsibility ensures that we meet the evolving needs of our customers and contribute to a better future for the industry.

Zhiyu is passionate about good products, good services, and good prices to let consumers know that choosing us is the right choice! For partners and end customers, we will provide one-on-one considerate smart services and provide you with more high-quality procurement solutions.