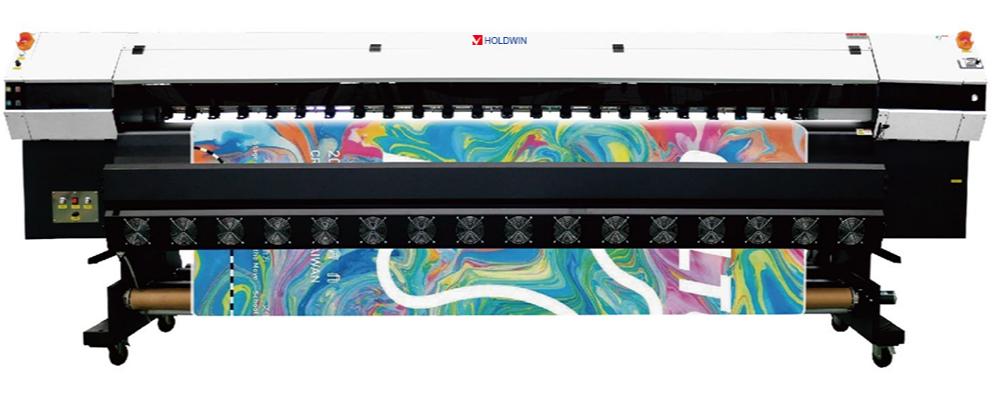

In the dynamic world of digital textile printing, achieving superior print quality is essential for success. As an industry leader, HOLDWIN is dedicated to providing cutting-edge solutions that empower textile manufacturers, fashion designers, and other stakeholders to produce exceptional prints. In this article, we will delve into various techniques and tips that can significantly optimize print quality, offering practical insights backed by the latest technological advancements and industry practices.

Digital textile printing has revolutionized the textile industry by offering unparalleled customization, precision, and efficiency. However, the key to standing out in a competitive market lies in the quality of the prints. Whether you are printing on clothing, towels, scarves, or carpets, achieving sharp, vibrant, and durable prints requires careful consideration of various factors. This article explores essential techniques and tips that can help you optimize print quality and ensure consistent results.

The choice of inks plays a critical role in determining the quality of digital prints. Different textile materials require specific types of inks to achieve the desired color vibrancy and durability. For instance, sublimation inks are ideal for polyester fabrics, while pigment inks are better suited for cotton. Understanding the chemical properties of inks and how they interact with various textiles is crucial.

To optimize print quality, it is essential to select high-quality inks that offer consistent color reproduction and resistance to fading. Additionally, the use of eco-friendly inks, such as water-based options, not only enhances print quality but also aligns with the growing demand for sustainable printing solutions.

The performance of digital printing machines directly influences the quality of the output. Regular calibration and maintenance of printing equipment are vital to ensure consistent print quality. Calibration involves adjusting the printer settings to achieve accurate color reproduction, while maintenance focuses on keeping the machinery in optimal condition.

Common maintenance practices include cleaning print heads, replacing worn-out components, and updating firmware. Regular inspections and preventive maintenance can prevent issues such as color banding, ink bleeding, and misalignment, all of which can negatively impact print quality.

Color management is a critical aspect of optimizing print quality. It involves the accurate reproduction of colors from the digital design stage to the final printed product. Effective color management ensures that the colors you see on the screen match those on the printed textile, reducing discrepancies and reprints.

To achieve this, it is essential to use ICC (International Color Consortium) profiles that are tailored to your specific printer, inks, and textile materials. These profiles help in maintaining color consistency across different batches and production runs. Additionally, investing in color calibration tools, such as spectrophotometers, can further enhance accuracy.

The quality of the digital design and file preparation also significantly impacts the final print output. High-resolution designs (typically 300 dpi) are essential to avoid pixelation and ensure sharpness. Additionally, preparing the files in the correct format, such as TIFF or PSD, preserves the integrity of the design elements.

When designing for digital textile printing, it is important to consider factors such as color gamut, fabric shrinkage, and bleed. Designing with these factors in mind can prevent common issues like color distortion and misalignment, ultimately leading to higher-quality prints.

Pre-treatment and post-treatment processes are critical to optimizing print quality, especially for textiles that require special handling. Pre-treatment involves preparing the fabric surface to receive the ink, which can include coating the fabric with chemicals that enhance ink absorption and adhesion.

Post-treatment, on the other hand, involves processes such as heat pressing or steaming to fix the inks and improve durability. Both treatments are essential for achieving vibrant colors, sharp details, and long-lasting prints.

Staying updated with the latest printing technologies is crucial for optimizing print quality. Technologies such as UV printing, which allows for printing on a wide range of materials, and hybrid printing, which combines the benefits of digital and traditional printing methods, offer new possibilities for achieving superior results.

At HOLDWIN, we are committed to innovation and continuously invest in advanced printing technologies to meet the evolving needs of our clients. By leveraging these technologies, we can deliver high-quality, customized solutions that set our clients apart in the market.

Optimizing print quality in digital textile printing is a multifaceted process that requires a deep understanding of inks, equipment, color management, design preparation, and treatment processes. By mastering these techniques and staying abreast of the latest technological advancements, textile manufacturers and fashion designers can achieve exceptional print results that resonate with their target audience.

At HOLDWIN, we are dedicated to helping our clients achieve their printing goals by providing cutting-edge solutions and personalized support. Whether you are looking to enhance your current production line or explore new possibilities in digital textile printing, we are here to assist you every step of the way.

Customer Testimonial: “Working with HOLDWIN has been a game-changer for our business. Their expertise in optimizing print quality has allowed us to deliver products that exceed our customers’ expectations. The level of detail and color vibrancy in our prints is simply unmatched. We couldn’t be happier with the results!” – Jane Doe, Fashion Designer

Zhiyu is passionate about good products, good services, and good prices to let consumers know that choosing us is the right choice! For partners and end customers, we will provide one-on-one considerate smart services and provide you with more high-quality procurement solutions.