Meidao Textile is a company specializing in textile printing services, providing high-quality printing for various garments and home textiles. However, as market demands become increasingly diverse and customer expectations rise, the traditional screen printing process has struggled to keep up in terms of production efficiency and quality control. Meidao Textile needed an advanced printing solution that could boost production efficiency, ensure consistent print quality, and reduce error rates.

Challenges of Traditional Processes

Before adopting digital printing technology, Meidao Textile relied heavily on traditional screen printing. While this method has a long history, it faced several significant challenges in modern production:

- Low Production Efficiency: Screen printing requires frequent template changes, especially when handling diverse, small-batch orders. This led to long production cycles and an inability to quickly respond to market demands.

- Inconsistent Quality: The manual nature of the process often resulted in misaligned prints and uneven colors, making it difficult to maintain consistent product quality.

- High Error Rates: The complexity and precision required for manual operations increased the risk of errors, leading to higher waste rates and impacting overall production costs and profitability.

Advanced Digital Printing Solution

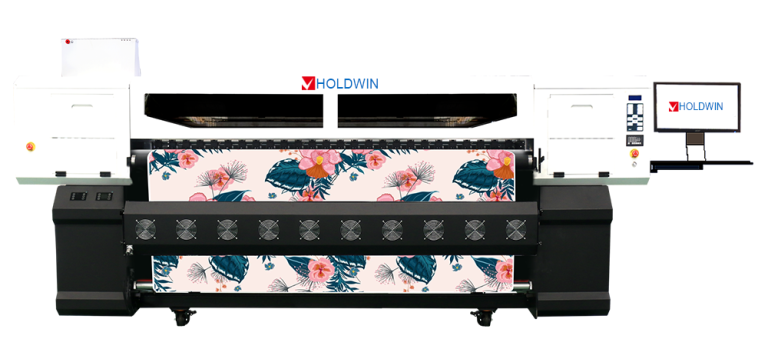

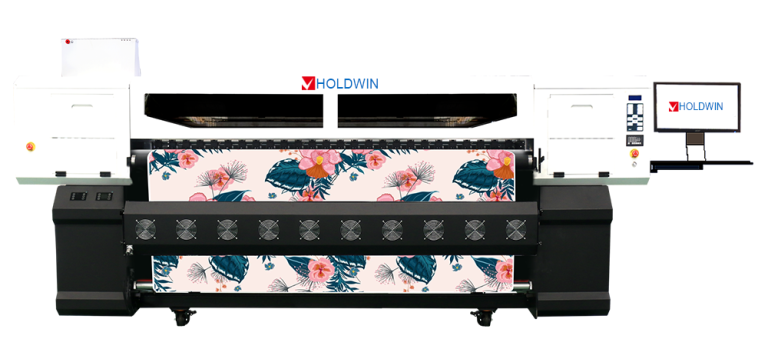

To address these challenges, we provided Meidao Textile with four HOLDWIN 8-head industrial-grade sublimation digital printing machines. These machines, with their exceptional performance and flexible operation, enabled Meidao Textile to fully upgrade their production process.

- High-Efficiency Production: The multi-head design and automated controls significantly increased printing speed, improving production efficiency by approximately 60%. This allowed Meidao Textile to respond more quickly to customer demands and reduce order lead times.

- High-Precision Printing: Digital printing technology delivers high-resolution, precise prints, ensuring vibrant colors and clear details in every batch, resulting in more consistent product quality.

- Ease of Operation: The user-friendly interface and automated features reduced the technical requirements for operators, significantly lowering the error rate and streamlining the production process.

- Enhanced Flexibility: The HOLDWIN digital printing machines support rapid switching between different patterns without the need to change physical templates, greatly enhancing the production line’s flexibility—especially valuable for small-batch, diverse orders.

Implementation and Optimization Process

During the implementation phase, we worked closely with Meidao Textile to ensure the smooth installation and commissioning of the digital printing machines. The specific steps were as follows:

- Needs Analysis: We first conducted a thorough analysis of Meidao Textile’s production process, product types, and specific needs to determine the most suitable equipment configuration.

- Equipment Installation: Our professional technical team traveled to Meidao Textile’s factory to install the equipment, ensuring seamless integration with their existing production lines. We followed strict protocols during installation to guarantee precision at every step.

- Training Support: We provided comprehensive training on equipment operation and maintenance to Meidao Textile’s staff, ensuring they could operate the machines proficiently and maintain them in optimal condition.

- Trial Operation and Optimization: During the trial phase, we monitored the equipment’s performance, collected feedback, and made necessary adjustments to parameters to ensure the machines operated at peak performance in Meidao Textile’s production environment.

Results and Feedback

Since the implementation of the HOLDWIN digital printing machines, Meidao Textile has seen significant improvements in both production efficiency and product quality. The key results include:

- Substantial Increase in Production Efficiency: Printing speed increased by approximately 60%, significantly shortening production cycles and allowing for quicker responses to market demands and customer orders.

- More Consistent Product Quality: Digital printing technology ensured uniformity in pattern alignment and color accuracy, leading to higher customer satisfaction and an increase in repeat orders.

- Improved Cost Control: The reduction in template changes and waste rates led to a 25% decrease in production costs, giving Meidao Textile a competitive edge in the market.

Meidao Textile expressed high praise for our digital printing solution: “Since introducing the HOLDWIN digital printing machines, our production efficiency and product quality have improved significantly. The equipment is easy to operate and maintain, which has greatly reduced errors and waste during production. We appreciate your company’s professional service and technical support, which have helped us upgrade our production process and take our business to new heights.”

Conclusion

Through this collaboration, Meidao Textile successfully transitioned from traditional screen printing to advanced digital printing, achieving significant improvements in both production efficiency and product quality. This case study highlights HOLDWIN’s leading technology in digital printing and our ability to provide tailored solutions for our clients. We remain committed to offering efficient, innovative printing solutions to help more clients achieve their business goals and success.