In the rapidly evolving world of textile manufacturing, digital printing has emerged as a pivotal technology, enabling businesses to offer personalized and custom solutions with incredible speed and precision. As more companies adopt digital printing technologies, the need for well-trained staff who can operate these machines effectively becomes crucial. Proper training not only maximizes the efficiency and lifespan of the equipment but also ensures high-quality output, meeting customer demands. This article will explore the key aspects of training staff for digital printing operations, focusing on practical strategies to ensure your team is well-equipped to handle the technology, from basic operation to advanced troubleshooting.

To effectively train staff, it’s essential to first understand the various digital printing technologies that dominate the textile industry. These include direct-to-garment (DTG), sublimation, UV printing, and DTF (Direct-to-Film) printing, each with its unique characteristics and operational requirements.

Training programs should begin with an overview of these technologies, explaining their differences, strengths, and ideal applications. For example, DTG is best suited for detailed, full-color designs on cotton-based textiles, while sublimation printing works exceptionally well on polyester fabrics, producing vibrant colors and durable prints. By understanding these distinctions, your staff can better choose the right process for each job, ensuring optimal results.

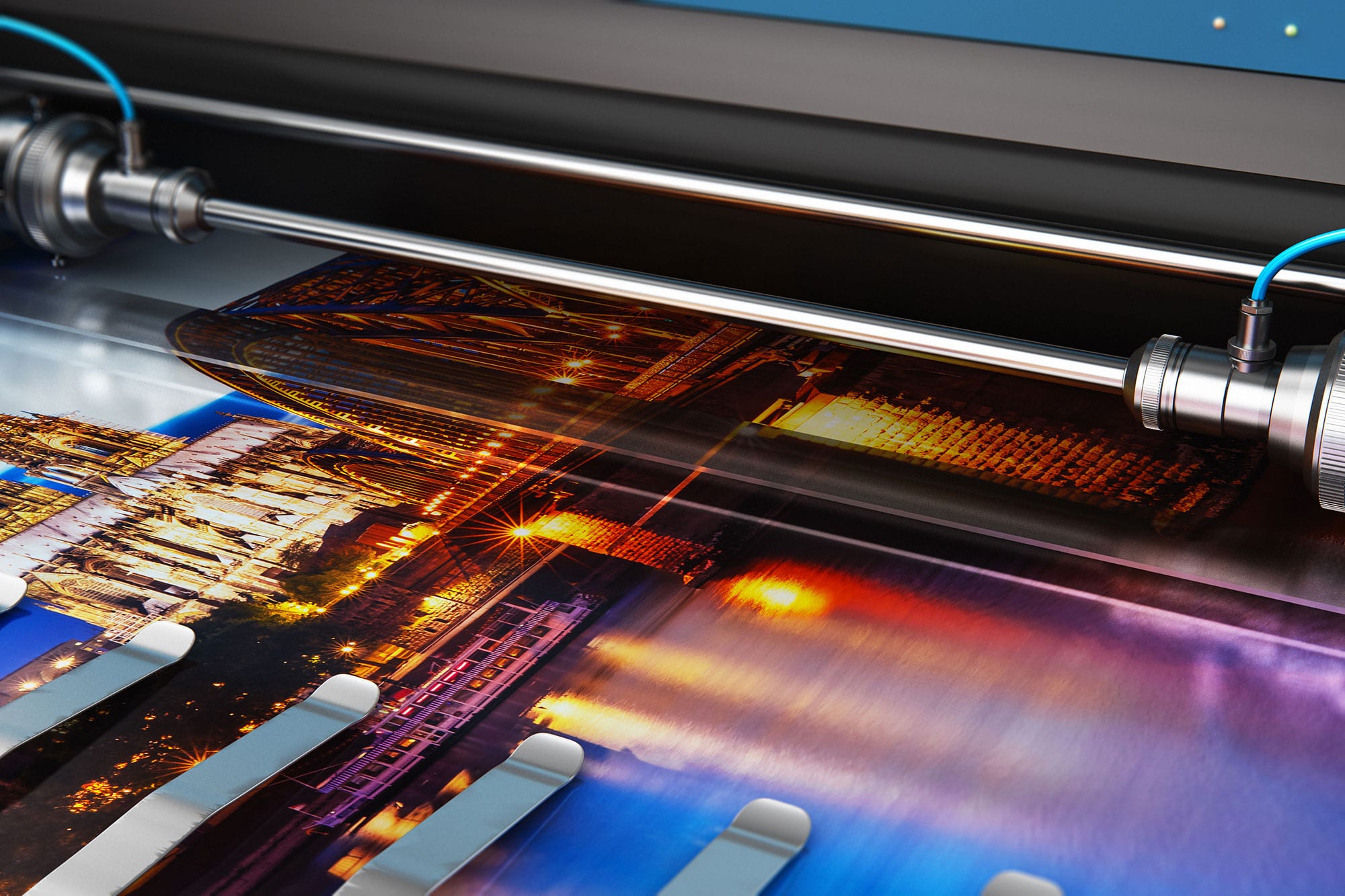

A major component of staff training is hands-on machine operation. Digital printers, like those provided by HOLDWIN, are equipped with advanced features, but these can be overwhelming without proper instruction. Training should cover machine setup, material loading, ink management, and maintenance procedures, ensuring that operators understand every aspect of the machinery.

It’s essential that your training sessions offer plenty of opportunities for hands-on practice, supervised by an experienced technician. This allows employees to become familiar with the machine’s user interface, printing speeds, and error handling. Additionally, employees should learn how to troubleshoot common issues like ink clogs, printhead misalignment, or color inconsistencies, empowering them to resolve problems without downtime.

In digital printing, mastering color management is critical to producing consistent, high-quality prints. Improper color settings can lead to wasted materials and unsatisfied customers. Training should cover color theory, profiling, and calibration processes, ensuring that your staff understands how to adjust color settings for different textiles and maintain consistency across batches.

Color management training should also include instruction on the use of software such as RIP (Raster Image Processor), which helps to manage color data and control the final output. This ensures that designs are printed exactly as intended, with accurate color reproduction that meets customer expectations.

Training must emphasize the importance of safety protocols and regular maintenance, both of which are key to the longevity and safe operation of digital printers. Staff should be trained in basic safety measures, such as proper handling of inks, solvents, and other chemicals, as well as the use of protective equipment.

Additionally, regular maintenance is essential for keeping machines in peak condition. Staff should be trained on how to perform routine cleaning, inspect parts for wear and tear, and recognize when a machine needs professional servicing. This not only reduces the risk of equipment breakdowns but also ensures consistent, high-quality output.

### Image 4: Maintenance Checklist

A detailed checklist of daily, weekly, and monthly maintenance tasks for a digital printer. The image should highlight essential activities like printhead cleaning, ink system inspection, and parts lubrication, ensuring that operators understand the importance of preventive care.

As digital printing continues to advance, training programs must evolve to include the latest technological developments. For example, hybrid printing technologies that combine UV and sublimation processes are gaining traction, offering new opportunities for textile customization. Employees should be trained to work with these technologies, understanding how they can expand the range of products the company can offer.

Moreover, HOLDWIN’s commitment to innovation means that our products are continually evolving. Staff must be trained not just on current systems but also on how to adapt to future upgrades. By maintaining a forward-looking training program, businesses can ensure their teams are prepared for new challenges and opportunities in the digital printing industry.

Effective staff training is the backbone of any successful digital printing operation. By providing comprehensive instruction on machine operation, color management, safety protocols, and advanced technologies, you can ensure your team is fully equipped to deliver top-tier results. In an industry driven by customization and quick turnaround times, well-trained staff are essential to staying competitive.

At HOLDWIN, we pride ourselves on offering not only cutting-edge digital printing equipment but also the training and support necessary to help our customers succeed. As one satisfied customer put it, “Since integrating HOLDWIN’s digital printers into our production line, our staff’s productivity has increased significantly. The training provided was clear, hands-on, and tailored to our needs. We’ve been able to expand our product offerings and improve our quality standards, thanks to HOLDWIN’s support.”

By investing in proper training, businesses can unlock the full potential of digital printing technology, driving growth and success in an ever-evolving industry.

1. Smith, A. (2021). *Digital Printing in Textile Manufacturing: Trends and Technologies.* Textile Science Journal, 56(4), 321-334.

2. Johnson, P. & Lee, H. (2020). *Advanced Color Management for Digital Printers.* Journal of Digital Printing Technology, 14(2), 89-103.

3. Williams, D. (2019). *Training Best Practices for Digital Print Operators.* International Journal of Textile Innovation, 12(1), 57-68.

4. Zhang, Q. (2022). *Future Trends in Hybrid Digital Printing Technologies.* Textile Printing Review, 30(6), 200-215.

5. Martinez, R. (2020). *Safety and Maintenance in Digital Printing Operations.* Journal of Textile Safety, 8(3), 45-58.

Zhiyu is passionate about good products, good services, and good prices to let consumers know that choosing us is the right choice! For partners and end customers, we will provide one-on-one considerate smart services and provide you with more high-quality procurement solutions.