In the vibrant world of textile printing, achieving consistent and accurate color output is paramount. Digital color management ensures that the colors in the final printed product match the designer’s vision, making it a critical aspect of digital textile printing. At HOLDWIN, we are dedicated to providing advanced digital printing solutions that cater to the evolving needs of our global clientele. In this article, we will explore the best practices for digital color management, ensuring your printed textiles always meet the highest standards of quality and consistency.

Digital color management encompasses the processes and technologies used to control color representation across different devices and materials. It involves the use of color profiles, calibration techniques, and software solutions to ensure that the colors viewed on a screen or digital file are faithfully reproduced on the final printed material. This is particularly important in textile printing, where variations in fabric type, ink, and printing technology can significantly impact color output.

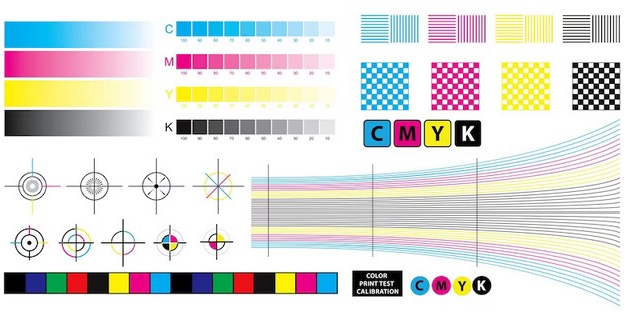

Color calibration is the process of adjusting the color output of a device to match a known standard. For digital printers, this involves calibrating the printer to ensure that it produces the correct colors based on a reference. Calibration should be performed regularly to account for changes in printer performance over time. Tools like spectrophotometers and colorimeters are essential for accurate calibration.

Color profiling involves creating a color profile for each device involved in the printing process. These profiles describe how colors should appear on a specific device and are used to translate colors between devices. For example, a monitor profile ensures that colors displayed on a screen are accurate, while a printer profile ensures that the printer reproduces these colors correctly on fabric.

Proofing is a critical step in the color management process, allowing designers to see a close approximation of the final printed product. Digital proofing techniques, such as soft proofing on calibrated monitors or hard proofing using test prints, help identify color issues early in the process. This ensures that adjustments can be made before the final print run, saving time and resources.

Regular calibration of all devices involved in the printing process is essential for maintaining color accuracy. Printers, monitors, and even cameras used for digital design should be calibrated at least once a month. Using high-quality calibration tools and software can help achieve consistent results.

Using standardized color profiles for different types of fabrics and inks can significantly improve color consistency. Profiles should be created for each combination of printer, ink, and fabric used in the production process. Additionally, profiles should be updated periodically to account for any changes in materials or equipment.

Implementing accurate proofing techniques is crucial for identifying and correcting color issues early. Soft proofing on a calibrated monitor allows designers to make adjustments before printing. Hard proofing, using test prints, provides a tangible reference to compare against the final product. Both methods help ensure that the printed colors match the designer’s expectations.

Investing in advanced color management software can streamline the entire process, from design to final print. Software solutions offer features like automatic profiling, real-time color adjustments, and integration with design tools. This reduces the complexity of managing colors and improves overall efficiency.

Spectrophotometers are essential tools for precise color measurement and calibration. They provide accurate readings of color values, which can be used to create and adjust color profiles. Incorporating spectrophotometers into the color management workflow ensures that colors are consistently reproduced across different batches and materials.

Modern digital printing technologies offer enhanced capabilities for color management. UV printers, for instance, provide high-resolution printing with excellent color accuracy, making them ideal for complex designs. By integrating advanced printing technologies with robust color management practices, textile manufacturers can achieve superior results.

At HOLDWIN, we understand the importance of precise color management in digital textile printing. Our commitment to innovation and quality ensures that our customers receive the best products and solutions. We continuously invest in research and development to bring the latest advancements in color management to our clients. Our ability to quickly develop new products and provide personalized solutions sets us apart in the industry.

“Since partnering with HOLDWIN, our color consistency has improved dramatically. Their advanced color management solutions and exceptional customer support have made a significant difference in our production quality.” — Alex Martinez, Textile Manufacturer.

Effective digital color management is crucial for achieving consistent, high-quality results in textile printing. By following best practices such as regular calibration, standardized profiling, accurate proofing, and leveraging advanced technologies, textile manufacturers can ensure that their printed products meet the highest standards. HOLDWIN remains dedicated to providing innovative solutions that help our clients succeed in the competitive world of textile printing.

Zhiyu is passionate about good products, good services, and good prices to let consumers know that choosing us is the right choice! For partners and end customers, we will provide one-on-one considerate smart services and provide you with more high-quality procurement solutions.