The digital printing industry has revolutionized textile manufacturing, offering faster, more versatile, and cost-effective methods for printing on a variety of materials. However, with the rapid growth of this sector, there has been increasing concern about the environmental impact, particularly regarding waste and energy consumption. As a leading company in the digital printing field, HOLDWIN is committed to reducing these environmental burdens by implementing sustainable practices and providing solutions that benefit both manufacturers and the planet. In this article, we explore the latest innovations in digital printing technology, strategies to minimize waste, and how energy efficiency can be achieved without compromising quality.

Digital printing is known for its ability to create high-quality designs with minimal setup time, but like all industrial processes, it comes with its environmental challenges. Waste and energy consumption are two key issues that need to be addressed. Printing machines often consume large amounts of energy, particularly in high-speed production environments. Additionally, waste can accumulate in the form of excess ink, faulty prints, and leftover materials.

A 2020 report by the World Economic Forum highlighted that the textile industry is one of the largest contributors to environmental degradation, with textile production accounting for 10% of global carbon emissions (WEF, 2020). While digital printing is more efficient than traditional methods in many ways, it still needs to adapt further to meet sustainability goals. Companies like HOLDWIN are taking the lead by developing technologies that significantly reduce both energy consumption and waste in the production process.

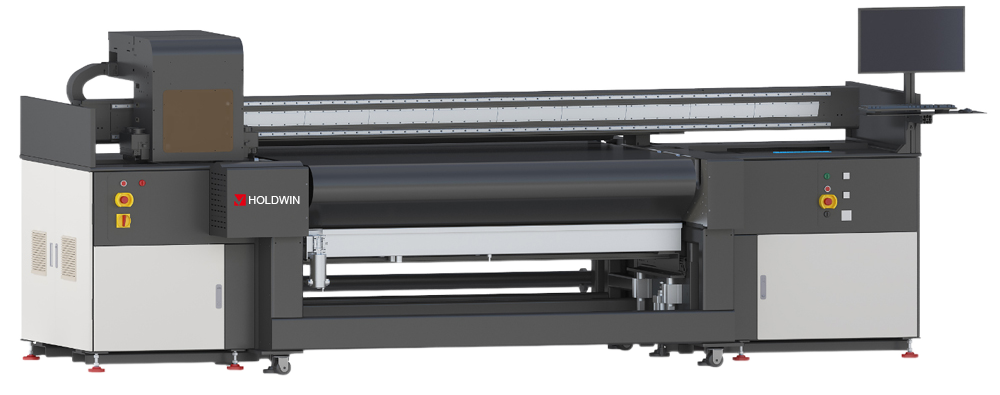

Excessive ink usage is one of the main contributors to waste in digital printing. Advanced inkjet technology, such as that used in HOLDWIN’s digital printers, allows for more precise ink control. By utilizing printheads that deposit ink with higher accuracy, manufacturers can minimize the amount of ink used during the printing process, reducing waste. Moreover, features like automatic ink circulation systems help prevent ink from drying in the lines, ensuring that every drop is used efficiently.

Fabric waste occurs when excess material is used or when the printer makes a mistake during the printing process. With HOLDWIN’s advanced cutting-edge software, fabric layouts can be optimized to maximize material usage. This software is capable of predicting the amount of fabric needed for each print job, allowing manufacturers to reduce scrap and increase material utilization.

Additionally, HOLDWIN’s heat transfer and sublimation printing technologies offer greater versatility, allowing printing directly onto fabric without the need for additional pre-treatment or finishing steps. This reduces the waste associated with chemical treatments or additional layers.

In many cases, the materials used in digital printing can be recycled. For example, some digital printers are compatible with eco-friendly inks and materials, such as water-based inks and recyclable transfer films. HOLDWIN is at the forefront of offering eco-friendly options, providing customers with solutions that help reduce the environmental impact. By using sustainable materials in production, manufacturers can significantly lower waste and reduce their carbon footprint.

Post-processing steps such as curing and drying can be major contributors to energy consumption and material waste. HOLDWIN’s printers are designed to work with low-energy drying systems, utilizing UV and heat technologies that reduce energy consumption during the curing process. This not only lowers electricity bills but also ensures that products are produced with minimal waste and reduced heat-related material degradation.

Energy consumption is another significant concern for digital printing companies. With the rapid advancements in printing technology, there are now several ways to achieve greater energy efficiency without sacrificing print quality. Here are some of the most effective strategies:

One of the simplest and most effective ways to reduce energy consumption is by upgrading to energy-efficient digital printing machines. Modern digital printers, such as those developed by HOLDWIN, are designed with energy-saving features like automatic shutdowns, energy-efficient motors, and low-power consumption during idle periods. These features contribute to substantial reductions in overall energy usage, especially in high-volume production environments.

Energy consumption can be minimized through efficient scheduling of print jobs. By consolidating smaller orders and reducing machine downtime, manufacturers can lower their overall energy expenditure. Software solutions from HOLDWIN allow for better planning and management of production schedules, ensuring that energy use is optimized throughout the production cycle.

Some companies are turning to renewable energy sources, such as solar power, to meet their energy needs. HOLDWIN encourages the adoption of sustainable energy solutions in textile production by offering equipment that is compatible with solar energy systems. By reducing reliance on fossil fuels, manufacturers can further reduce their carbon footprint and improve sustainability.

Technology is a key enabler of sustainability in the digital printing sector. Innovations such as AI-powered print management systems, energy-efficient hardware, and eco-friendly inks are all playing a significant role in reducing waste and energy consumption. HOLDWIN is committed to staying ahead of these trends by continuously innovating and providing solutions that help manufacturers reduce their environmental impact.

As part of its global vision, HOLDWIN seeks to become a world-renowned leader in digital printing by focusing on sustainable practices. The company’s commitment to providing personalized solutions, innovative products, and energy-efficient technology reflects its dedication to both business success and environmental responsibility.

“As a manufacturer, we’ve always been concerned about the environmental impact of our production processes. After adopting HOLDWIN’s digital printing solutions, we’ve seen a significant reduction in both waste and energy costs. The ink optimization technology and energy-efficient machines have not only helped us meet our sustainability goals but have also improved our bottom line. We’re proud to be working with a company that shares our commitment to a greener future.”

Reducing waste and energy consumption in digital printing is essential for the industry’s long-term sustainability. Through innovations in ink usage, fabric optimization, energy-efficient machines, and smart production scheduling, companies like HOLDWIN are leading the way in promoting environmentally responsible practices. By adopting these solutions, manufacturers can not only reduce their environmental footprint but also enhance operational efficiency and drive long-term profitability. As the digital printing industry continues to evolve, sustainability will remain at the heart of technological advancements, helping shape a more eco-conscious future for all.

References:

World Economic Forum. (2020). The Fashion Industry and Its Impact on the Environment. Retrieved from https://www.weforum.org

Zhiyu is passionate about good products, good services, and good prices to let consumers know that choosing us is the right choice! For partners and end customers, we will provide one-on-one considerate smart services and provide you with more high-quality procurement solutions.