In the fast-paced world of textile printing, the efficiency and reliability of digital printing machines are crucial to maintaining production timelines and ensuring high-quality outputs. For textile manufacturers, fashion designers, and digital printing equipment buyers, understanding the maintenance of these machines is not just a technical necessity but a strategic investment in sustaining business operations. This article will provide comprehensive maintenance tips for digital printing machines, ensuring that your investment in this advanced technology pays off in the long run. HOLDWIN, a leading brand in the digital printing industry, is committed to offering top-tier solutions, reflecting our global vision to be recognized as a world-renowned brand. We understand the importance of machine maintenance in maximizing productivity and minimizing downtime, and we’re here to guide you through the best practices.

Digital printing machines, whether for heat transfer, sublimation, DTF, UV, or solvent printing, are complex systems that require regular maintenance to function at their best. Neglecting maintenance can lead to decreased print quality, frequent machine breakdowns, and higher operational costs due to unscheduled repairs and parts replacements. Regular maintenance ensures that the machine operates efficiently, reducing the risk of downtime and extending the lifespan of the equipment.

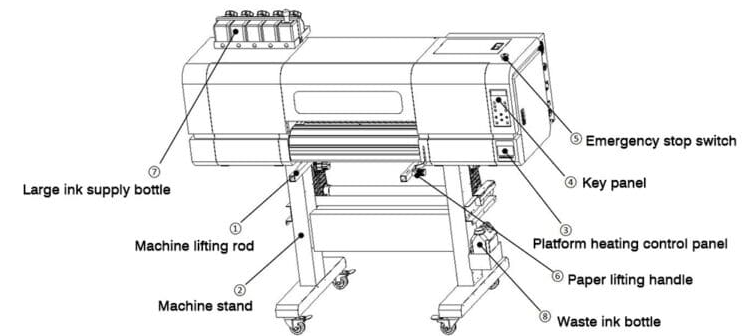

Daily maintenance is the cornerstone of keeping digital printing machines in optimal condition. This routine involves cleaning the printheads, inspecting ink levels, and ensuring that all moving parts are lubricated and free of debris. For instance, in sublimation printing, it’s crucial to clean the printheads daily to prevent clogs that can disrupt the flow of ink and result in poor print quality. Similarly, checking the rollers for any signs of wear and tear can prevent misalignments that might cause errors during the printing process.

At HOLDWIN, we recommend setting up a daily checklist for operators to follow, ensuring consistency and thoroughness in maintenance tasks. This proactive approach not only preserves the quality of the prints but also reduces the likelihood of sudden machine failures.

While daily routines are essential, weekly and monthly maintenance practices address deeper aspects of machine care. Weekly maintenance should include more thorough cleanings, such as purging the ink lines and checking the alignment of the printheads. For UV printers, it’s important to inspect the UV lamps to ensure they are functioning correctly, as faulty lamps can result in incomplete curing of the ink.

Monthly maintenance, on the other hand, involves more extensive checks and replacements. This includes calibrating the machine to maintain color accuracy, inspecting the belts and gears for any signs of wear, and replacing any worn-out parts. Additionally, for solvent printers, it’s recommended to clean the filters and ventilation system to prevent the build-up of harmful fumes that could affect both the machine and the operators.

Even with regular maintenance, digital printing machines can encounter issues that require immediate attention. Common problems include ink clogging, color banding, and misalignment of prints. Understanding the root causes of these issues and how to troubleshoot them can save time and prevent costly downtime.

For example, ink clogging is often caused by dried ink residues in the printhead nozzles, which can be resolved by performing a deep cleaning cycle. Color banding, on the other hand, might be due to misalignment of the printheads or inconsistent ink flow, which can be corrected by recalibrating the machine and checking the ink supply system.

At HOLDWIN, our machines are designed with user-friendly interfaces that guide operators through troubleshooting processes, minimizing the need for external technical support. This not only empowers operators but also reduces operational costs and enhances the overall efficiency of the production line.

Preventive maintenance goes beyond daily and periodic routines by focusing on preemptive measures to avoid potential problems. This approach involves regularly updating software and firmware, keeping spare parts on hand, and scheduling professional inspections. By anticipating issues before they arise, companies can significantly reduce downtime and extend the life of their digital printing machines.

For instance, updating the machine’s software can optimize its performance, ensuring compatibility with the latest printing technologies and materials. Additionally, having a stock of essential spare parts, such as printheads, belts, and rollers, allows for quick replacements, minimizing interruptions in the production process.

At HOLDWIN, we emphasize the importance of preventive maintenance as part of our commitment to providing high-quality, reliable digital printing solutions. Our global vision drives us to continuously innovate and offer products that meet the evolving needs of our customers, ensuring their success in the competitive textile printing industry.

As a leader in the digital printing industry, HOLDWIN is dedicated to providing cutting-edge solutions that meet the highest standards of quality and performance. Our commitment to innovation is reflected in our ability to quickly develop new products and offer personalized solutions tailored to the unique needs of our customers. By prioritizing maintenance, we ensure that our machines deliver consistent, high-quality results, helping our clients stay ahead in the competitive textile market.

A satisfied customer from South America recently shared their experience: “Since switching to HOLDWIN’s digital printing machines, we’ve seen a significant improvement in print quality and overall efficiency. The user-friendly maintenance guidelines have made it easy for our team to keep the machines running smoothly, with minimal downtime. We’re extremely pleased with the results and the support we’ve received from HOLDWIN.”

Maintaining digital printing machines is an essential aspect of ensuring their longevity and consistent performance. By following daily, weekly, and monthly maintenance routines, troubleshooting common issues, and adopting preventive maintenance practices, operators can maximize their machines’ lifespan and maintain high-quality output. HOLDWIN’s commitment to innovation and customer satisfaction is evident in our comprehensive support and cutting-edge technology, helping our clients succeed in the ever-evolving textile printing industry. As the industry continues to advance, those who prioritize maintenance will be well-positioned to leverage new opportunities and maintain a competitive edge.

Zhiyu is passionate about good products, good services, and good prices to let consumers know that choosing us is the right choice! For partners and end customers, we will provide one-on-one considerate smart services and provide you with more high-quality procurement solutions.