Sublimation printing has revolutionized the textile industry, offering unparalleled quality and versatility for a wide range of applications. As the demand for personalized and high-quality textile products grows, sublimation printing has emerged as a preferred method for fashion designers, textile manufacturers, and digital printing technology enthusiasts. This guide delves into the intricacies of sublimation printing, exploring its techniques, applications, and benefits. At HOLDWIN, we are dedicated to leveraging the latest advancements in sublimation printing to provide cutting-edge solutions for our clients worldwide.

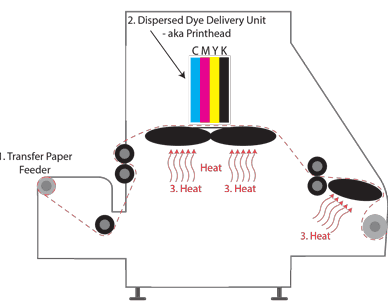

Sublimation printing is a process that involves transferring dye onto a material using heat. The unique aspect of sublimation is that the dye transitions from a solid to a gas without becoming liquid. This process embeds the dye into the fibers of the material, resulting in vibrant, durable prints that resist fading and cracking.

Sublimation printing works best on polyester fabrics or polymer-coated substrates. The essential equipment includes a sublimation printer, sublimation inks, transfer paper, and a heat press. The choice of equipment can significantly affect the quality and efficiency of the printing process.

One of the primary advantages of sublimation printing is the superior quality of prints. The colors are vibrant, and the details are sharp, making it ideal for producing high-resolution images and intricate designs. The prints are also resistant to washing, making them suitable for a variety of textile applications.

Sublimation printing offers incredible versatility. It can be used on a wide range of products, including clothing, towels, scarves, and carpets. This technology allows for high levels of customization, making it perfect for personalized products and small batch production.

Sublimation printing is also an eco-friendly process. It produces minimal waste compared to traditional printing methods, as there are no excess dyes or inks. Additionally, the use of water-based inks ensures that the process is less harmful to the environment.

Sublimation printing is widely used in the fashion industry to create unique and vibrant clothing items. From custom t-shirts to high-fashion garments, the ability to produce high-quality, durable prints makes sublimation a popular choice among designers.

In the home décor sector, sublimation printing is used to produce items such as custom cushions, curtains, and wall hangings. The ability to print on a variety of textiles allows for endless design possibilities, catering to diverse consumer preferences.

Sublimation printing is also prevalent in the production of promotional products. Items such as mugs, keychains, and phone cases can be personalized with company logos or custom designs, making them ideal for marketing and branding purposes.

Effective color management is crucial in sublimation printing to ensure that the colors on the printed material match the original design. This involves using the correct color profiles and calibrating the printer regularly.

Regular maintenance of sublimation printing equipment is essential to maintain print quality and prolong the lifespan of the machines. This includes cleaning the print heads, checking for clogs, and ensuring that the heat press maintains consistent temperature and pressure.

The future of sublimation printing looks promising, with continuous technological advancements enhancing print quality and efficiency. Innovations such as faster print speeds, automated workflows, and improved ink formulations are expected to drive the industry forward.

With an increasing focus on sustainability, the development of eco-friendly inks and energy-efficient equipment is gaining momentum. HOLDWIN is committed to leading the charge in sustainable practices, ensuring that our products not only meet but exceed environmental standards.

Sublimation printing offers unmatched quality, versatility, and eco-friendliness, making it an indispensable tool in the textile industry. At HOLDWIN, we are proud to be at the forefront of this technology, providing innovative and customized solutions to meet the diverse needs of our clients. Our commitment to quality and sustainability ensures that we remain a trusted partner in the digital printing landscape. As one satisfied customer, Jane Smith, a renowned fashion designer, remarked, “HOLDWIN’s sublimation printing technology has transformed our design process, allowing us to create vibrant and durable prints that our clients love.”

Zhiyu is passionate about good products, good services, and good prices to let consumers know that choosing us is the right choice! For partners and end customers, we will provide one-on-one considerate smart services and provide you with more high-quality procurement solutions.