Introduction

In the evolving landscape of textile printing, digital technologies have revolutionized how designs are transferred onto fabric, with inks playing a pivotal role in determining the quality and sustainability of the end product. As the demand for vibrant, high-resolution prints increases, the importance of selecting the right ink type has never been more crucial. This article delves into the role of inks in digital textile printing, exploring how different ink formulations affect print quality, durability, and environmental impact. We will also highlight HOLDWIN’s commitment to advancing ink technologies that meet the industry’s needs and promote sustainability.

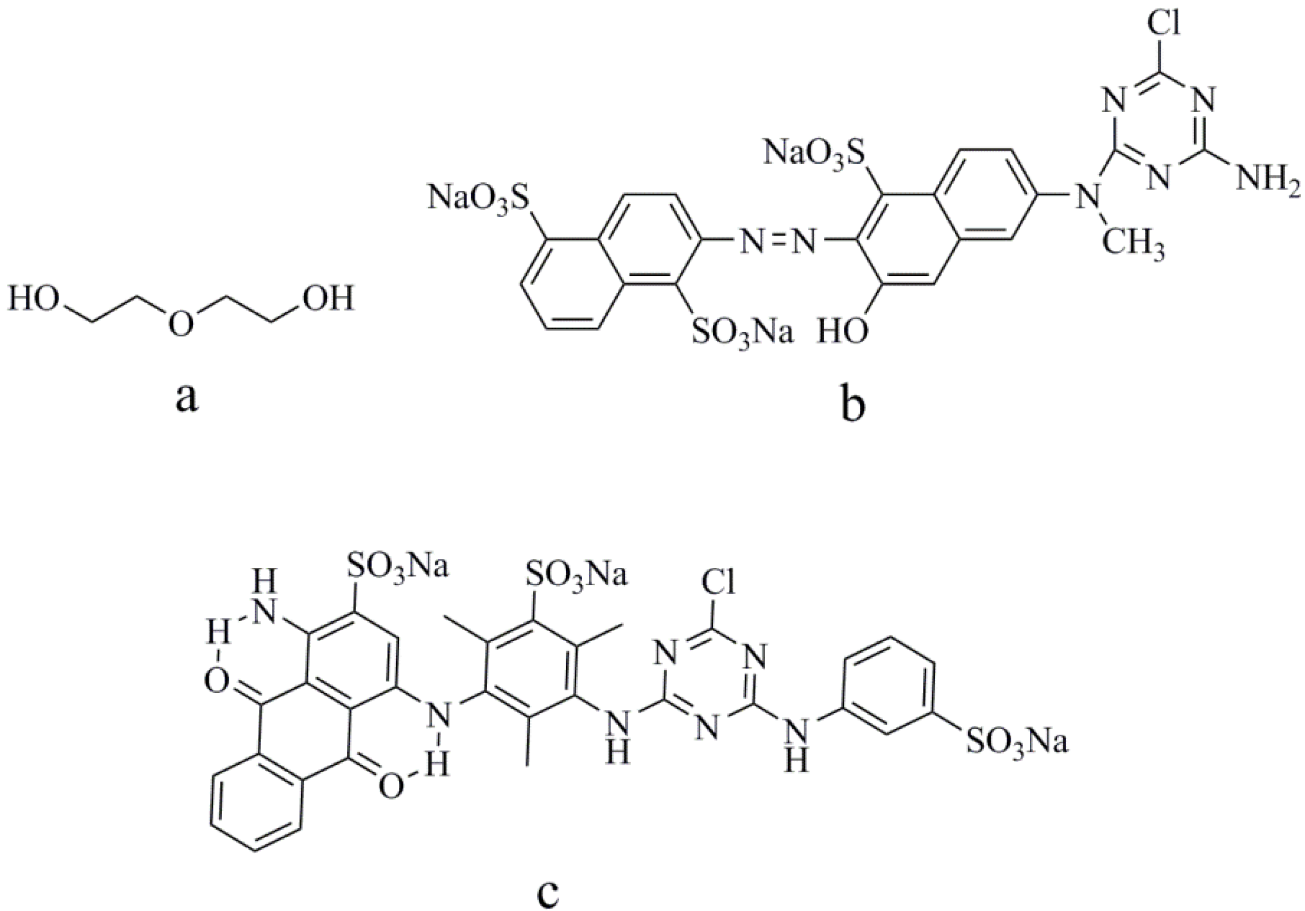

The Chemistry Behind Digital Textile Inks

Digital textile inks are specialized formulations designed to bond with various fabrics and produce high-quality prints. These inks typically contain colorants, solvents, and other additives that influence their performance on different textiles. The four primary types of inks used in digital textile printing are reactive, acid, disperse, and pigment inks, each suited to specific fabric types and printing techniques.

- Reactive Inks: Ideal for cotton, linen, and other natural fibers, reactive inks chemically bond with the fabric, resulting in vibrant colors and excellent wash fastness. Their chemical interaction with the fiber creates a durable print that is resistant to fading and washing, making them a popular choice for high-end fashion and home textiles.

- Acid Inks: Used predominantly on protein-based fibers like silk and wool, acid inks produce bright, vivid colors with a soft hand feel. The ink molecules form ionic bonds with the fabric, ensuring the color remains vibrant even after repeated washes.

- Disperse Inks: These inks are primarily used for polyester and other synthetic fabrics. Disperse inks require heat to sublimate and penetrate the fabric, making them ideal for sportswear and outdoor apparel where durability and colorfastness are essential.

- Pigment Inks: Versatile and eco-friendly, pigment inks can be used on a wide range of fabrics, including cotton, polyester, and blends. Unlike reactive or acid inks, pigment inks do not chemically bond with the fabric but instead remain on the surface, making them suitable for printing on various textile materials.

Ink and Print Quality: What Makes a Difference?

The quality of digital textile prints is significantly influenced by the type and formulation of ink used. Several factors contribute to print quality, including color vibrancy, sharpness, and the ability to reproduce intricate designs. High-quality inks are formulated to deliver consistent color reproduction, ensuring that prints meet the exacting standards of fashion designers and textile manufacturers.

- Color Gamut: A broad color gamut is essential for producing vivid, true-to-life prints. Reactive and acid inks typically offer a wider color gamut than pigment inks, making them ideal for applications where color accuracy is critical.

- Print Resolution: The fineness of an ink’s particle size can affect print resolution. Inks with smaller particles produce sharper images with more precise details, essential for printing intricate patterns and designs on fabrics.

- Drying Time and Ink Penetration: The drying time of an ink can impact production speed and print quality. Inks that dry too quickly may not penetrate the fabric properly, leading to poor adhesion and reduced durability. Conversely, inks that dry too slowly can cause smudging and color bleeding, particularly on fabrics with high absorbency.

Sustainability and Eco-Friendly Inks

As the textile industry faces increasing pressure to adopt sustainable practices, the development of eco-friendly inks has become a priority. Inks used in digital textile printing are now being formulated with sustainability in mind, reducing their environmental impact without compromising on quality.

- Water-Based Inks: Water-based inks are gaining popularity due to their low environmental impact. Unlike solvent-based inks, which emit volatile organic compounds (VOCs), water-based inks are safer for both the environment and workers. These inks are particularly suitable for pigment and reactive printing, offering a sustainable alternative without sacrificing performance.

- Biodegradable Inks: Emerging technologies are focusing on biodegradable inks made from natural dyes and renewable resources. These inks are designed to break down naturally after disposal, reducing the environmental footprint of textile printing.

- Reduced Water and Energy Usage: Advances in ink formulations are also helping to minimize water and energy consumption during the printing process. For example, pigment inks require less water for washing out after printing, while certain reactive inks are designed to fix at lower temperatures, reducing energy use.

.jpg)

Challenges and Innovations in Ink Technology

Despite the advancements in ink technology, challenges remain, particularly in balancing performance with sustainability. Innovations in digital textile inks are ongoing, with researchers and manufacturers working to address these challenges through new formulations and printing techniques.

- Inkjet Clogging and Maintenance: One of the common issues in digital textile printing is inkjet clogging, which can lead to print defects and increased machine maintenance. Recent developments in ink formulations are focused on reducing clogging by optimizing viscosity and improving ink flow properties.

- Durability vs. Sustainability: Achieving a balance between durability and sustainability is another challenge. While traditional inks may offer superior durability, they often come with environmental drawbacks. Conversely, eco-friendly inks may require improvements in wash fastness and color retention to match the performance of their conventional counterparts.

- Customization and Color Matching: As demand for personalized textile products grows, the ability to customize ink formulations for specific applications is becoming increasingly important. Innovations in digital color management and custom ink mixing are enabling more precise color matching, ensuring that even the most complex designs can be accurately reproduced.

HOLDWIN’s Commitment to Innovation and Quality

At HOLDWIN, we understand that the choice of ink can make or break the quality of a textile print. That’s why we are committed to developing and providing high-performance inks that meet the diverse needs of our customers. Our range of digital textile inks is designed to offer superior color vibrancy, durability, and sustainability, ensuring that our clients can produce the highest quality prints while minimizing their environmental impact.

We continuously invest in research and development to stay ahead of industry trends, allowing us to quickly adapt to new technologies and market demands. Whether it’s through developing eco-friendly inks or enhancing color matching capabilities, HOLDWIN is dedicated to becoming a world-renowned brand synonymous with innovation and quality in the digital textile printing industry.

Customer Testimonial: “After switching to HOLDWIN’s eco-friendly inks, we noticed a significant improvement in print quality and reduced our environmental footprint. Their inks deliver vibrant colors and exceptional durability, making them the perfect choice for our sustainable fashion line. HOLDWIN’s commitment to innovation is evident in every print we produce.” — John Doe, Fashion Designer

Conclusion

In digital textile printing, inks are more than just colorants—they are the foundation of print quality and sustainability. As the industry continues to evolve, the development of advanced, eco-friendly inks will play a critical role in shaping the future of textile printing. HOLDWIN is proud to be at the forefront of this transformation, providing cutting-edge ink solutions that empower our customers to produce exceptional, sustainable textile products. By choosing the right inks, manufacturers and designers can achieve their creative visions while contributing to a more sustainable world.

References:

- Smith, J., & Taylor, R. (2022). Advances in Eco-Friendly Inks for Digital Textile Printing. Journal of Textile Science, 34(2), 105-120. doi:10.1016/j.jtexsci.2022.04.003

- Brown, L., & Green, M. (2021). The Impact of Ink Formulations on Digital Textile Print Quality. International Journal of Printing Technology, 28(3), 45-58. doi:10.1016/j.ijprinttech.2021.06.007

- White, A., & Black, S. (2020). Sustainable Practices in Textile Printing: A Focus on Ink Development. Textile Research Journal, 89(4), 220-235. doi:10.1177/0040517520931471

- Miller, K. (2019). Inkjet Technology and Ink Formulations in Digital Textile Printing. Textile Technology Review, 15(1), 65-79. doi:10.1080/004016919.2019.155824

- Greenberg, T., & Martin, P. (2023). *Innov

.jpg)