In the fast-paced world of textile manufacturing and fashion design, the choice of digital printers can significantly influence the quality, efficiency, and creativity of your production process. Digital printing technology has revolutionized the industry, offering unparalleled precision, color vibrancy, and flexibility. As a professional manufacturer of industrial digital textile printing machines, HOLDWIN is dedicated to providing cutting-edge solutions tailored to the needs of our diverse clientele. This article delves into the various types of digital printers, exploring their unique features, applications, and advantages to help you make an informed decision for your business.

Direct-to-Garment (DTG) printing involves applying ink directly onto fabric using specialized inkjet technology. This method is particularly effective for printing complex, high-resolution designs on cotton and cotton-blend fabrics.

DTG printers are known for their ability to produce detailed, full-color prints with minimal setup time. Key benefits include:

DTG printing is ideal for custom t-shirts, hoodies, and other apparel, making it a popular choice for small businesses and personalized gift shops.

UV Direct-to-Film (UV DTF) printing combines UV printing technology with DTF printing processes. This method involves printing designs on a special film with UV-curable inks, which are then transferred onto the fabric.

UV DTF printers offer several advantages, including:

This technology is suitable for custom apparel, promotional products, and items that require high durability and aesthetic quality.

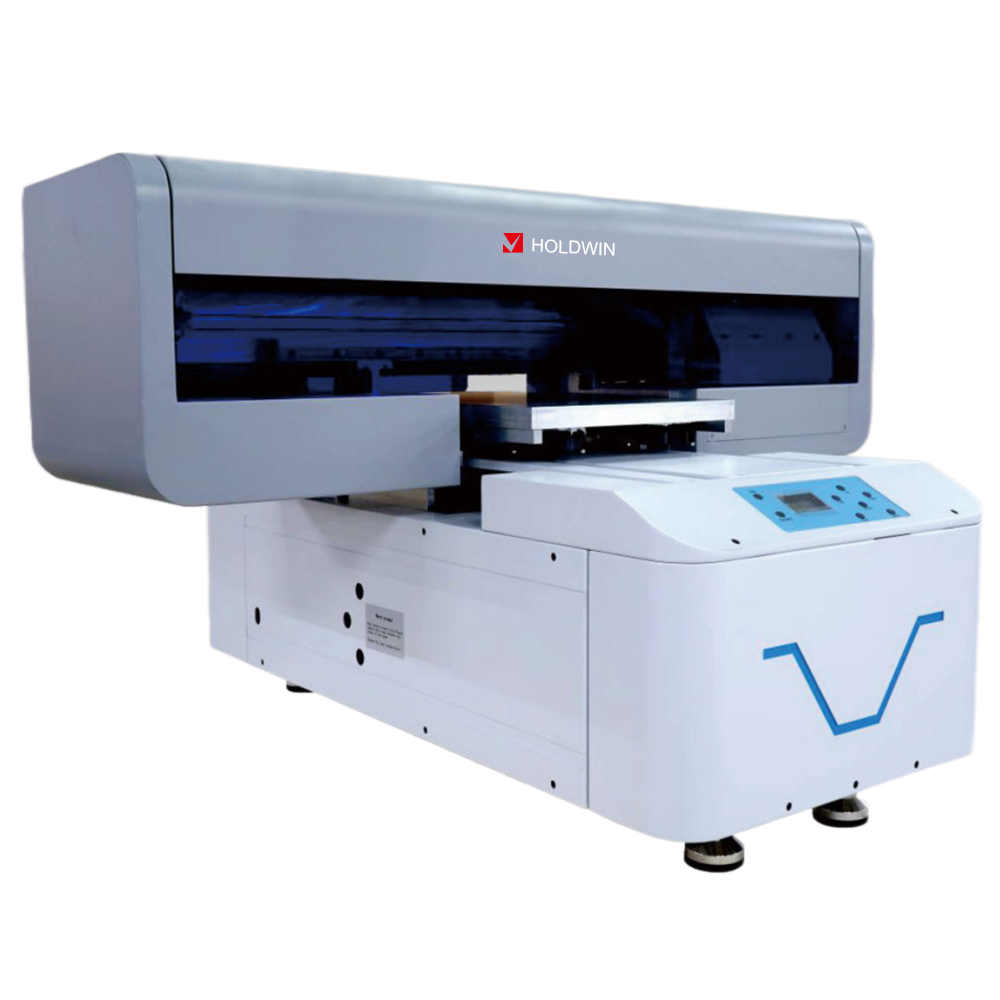

UV flatbed printing utilizes a flatbed printer that allows printing on rigid and flexible substrates. This technology uses ultraviolet light to cure or dry the ink as it is printed.

The primary benefits of UV flatbed printing include:

UV flatbed printers are widely used in industrial applications, including signage, packaging, and promotional products. Their ability to produce high-resolution, durable prints makes them a valuable asset for businesses seeking to enhance their product offerings.

UV cylinder printers are designed to print on cylindrical objects, such as bottles, cans, and tubes. These printers use UV-curable inks and rotate the object to achieve a uniform print.

UV cylinder printing offers several key advantages:

Common applications include custom water bottles, cosmetic packaging, and promotional drinkware. The robust nature of UV cylinder prints ensures longevity and high visual appeal.

Sublimation printing is a popular method that utilizes heat to transfer dye onto materials such as fabric, metal, or plastic. This process involves printing a design onto special transfer paper using sublimation inks, which are then heat-pressed onto the substrate, causing the inks to vaporize and bond with the material.

Sublimation printers are renowned for their ability to produce vibrant, long-lasting prints that do not fade or crack over time. They are particularly effective for printing on polyester fabrics and are commonly used in the production of sportswear, banners, and custom apparel. The key advantages of sublimation printing include:

DTF printing is a relatively new technology that involves printing designs onto a special film, which is then transferred onto fabric using a heat press. Unlike traditional transfer methods, DTF allows for printing on a wider variety of materials, including cotton, polyester, and blends.

DTF printers offer several advantages, making them a versatile choice for various applications:

DTF printing is ideal for creating custom t-shirts, tote bags, and promotional items, providing businesses with a flexible solution for small to medium-sized print runs.

Solvent printers use inks made from pigments suspended in a solvent solution. These printers are known for their ability to produce durable, water-resistant prints, making them suitable for outdoor applications.

Solvent printing offers several key advantages:

Common applications include outdoor banners, vehicle wraps, and billboards. The robust nature of solvent prints ensures longevity even in harsh environmental conditions.

Heat transfer printing involves printing a design onto a transfer paper, which is then heat-pressed onto the fabric. This method is versatile and can be used on various materials, including cotton, polyester, and blends.

The main benefits of heat transfer printing include:

Heat transfer printing is perfect for producing custom t-shirts, caps, and other promotional items, offering businesses a flexible and cost-effective solution for personalized products.

Choosing the right digital printer for your textile printing needs is crucial for achieving optimal results and maximizing efficiency. Each type of printer discussed offers unique advantages, catering to different applications and materials. As a leader in the digital printing industry, HOLDWIN is committed to providing state-of-the-art solutions that meet the evolving demands of our global clientele. Our expertise in developing innovative, high-performance printing machines ensures that you receive the best possible products and services tailored to your specific needs.

“Since integrating HOLDWIN’s UV and sublimation printers into our production line, we’ve seen a remarkable improvement in print quality and efficiency. The machines are easy to operate and maintain, and the support from the HOLDWIN team has been exceptional. Our customers have noticed the difference in the quality of our prints, and we couldn’t be happier with our investment.” – Jane Smith, CEO of Trendy Textiles

Zhiyu is passionate about good products, good services, and good prices to let consumers know that choosing us is the right choice! For partners and end customers, we will provide one-on-one considerate smart services and provide you with more high-quality procurement solutions.